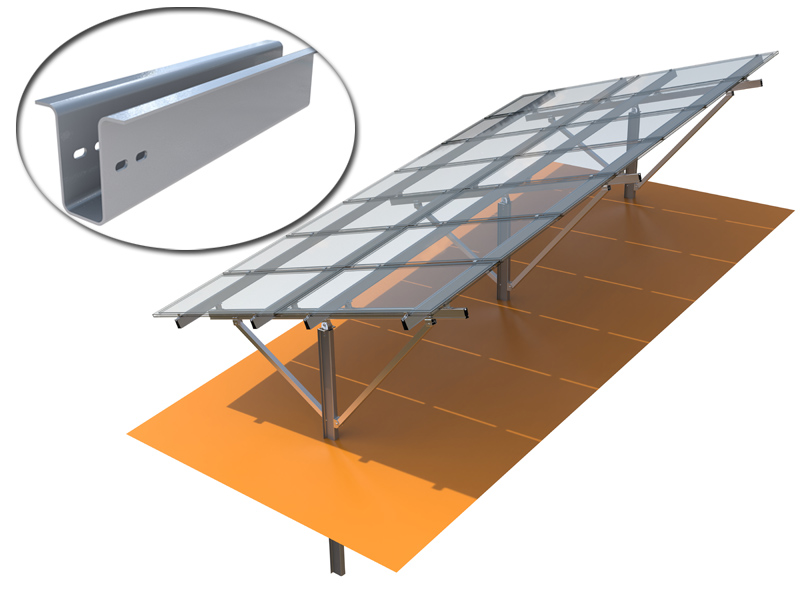

Sistemas de montaje solar Deben ser resistentes durante más de 25 años, incluso en condiciones climáticas adversas. Por eso, el acero aleado con zinc, aluminio y magnesio (ZAM) se está convirtiendo rápidamente en la opción preferida para proyectos fotovoltaicos en todo el mundo. Sus ventajas únicas solucionan los principales problemas de los materiales tradicionales, lo que impulsa su creciente popularidad en la industria solar.

1.Resistencia a la corrosión de 5 a 10 veces mayor

El recubrimiento Zn-Al-Mg de ZAM ofrece una durabilidad inigualable, superando al acero galvanizado en caliente entre 5 y 10 veces. Resiste la corrosión roja durante más de 3000 horas en pruebas de niebla salina, lo que lo hace ideal para zonas costeras, granjas fotovoltaicas agrícolas con alta humedad y zonas industriales. Con una vida útil de más de 30 años, elimina la necesidad de reemplazar los soportes prematuramente.

2.Bordes autorreparables revolucionarios

Cortar o perforar el acero tradicional daña su capa protectora, lo que provoca oxidación. ZAM soluciona este problema con su tecnología de autorreparación: los iones de magnesio forman una película protectora en los bordes expuestos, sin necesidad de procesamiento posterior. Esto ahorra tiempo y costes en proyectos de gran envergadura.

3.Ligero, resistente y económico

El ZAM es entre un 30 % y un 50 % más ligero que el acero tradicional, pero igual de resistente, lo que reduce los costes de transporte e instalación. Si bien la inversión inicial es ligeramente superior, la ausencia de mantenimiento durante décadas reduce el coste total de propiedad en más de un 10 %.

4.Ecológico y versátil

Libre de metales pesados, ZAM cumple con estándares ecológicos globales como el REACH de la UE. Es apto para sistemas fotovoltaicos en tejados, suelo y marquesinas, con diseños estandarizados para un montaje rápido.

Desde los proyectos de tejados de 785 kW en Singapur hasta las granjas solares costeras, ZAM demuestra ser más que un material: es una solución fiable y rentable para las necesidades a largo plazo de la energía solar. A medida que el sector busca mayor durabilidad y rentabilidad, la popularidad de ZAM seguirá en aumento. ¿Quiere saber cómo ZAM se adapta a su próximo proyecto fotovoltaico? ¡Póngase en contacto con proveedores de confianza para obtener soluciones a medida!

L-V 9AM a 18:00

L-V 9AM a 18:00  admin@cowellxm.com

admin@cowellxm.com

315 No.13 Malong Road, Huli District,Xiamen City, Fujian Province,China

315 No.13 Malong Road, Huli District,Xiamen City, Fujian Province,China